|

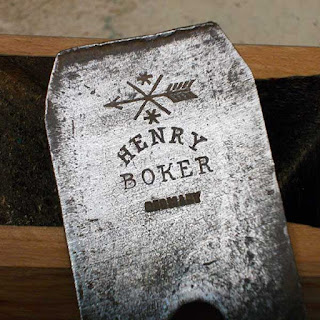

| The new blade (in the foreground) has a 5mm cutting edge. |

I have an old plough plane (used for cutting grooves) that I bought via TradeMe several years ago.

It's not quite in tip-top condition; it's missing its depth-stop for a start, which is a fairly necessary component, and the rosewood fence is quite worn. However, it's still usable, but it came with only a single blade — 11mm wide, which seems to me to be quite an odd size: it would be about 28/64" if one were still using those archaic measurement units from Olden Times.

Anyway, when I was out exploiting the skills and labour of my friend Nick recently, he gave me a piece of 3mm 01 steel to have a go at making blades for it in more useful sizes, and I finally got around to giving it a try.

It was not difficult, and I whipped up this one in fairly short order — I wasn't timing myself, but I think it was about an hour. The steel is quite soft and easy to work at the moment, so it cuts easily with a cutoff wheel and hacksaw. It would be quicker still if I had a metal blade for my bandsaw, but never mind.

Now I just need to heat-treat the new blade to harden it, and then put a decent edge on it. If it works as I hope and expect, I'll go ahead and make several more in useful sizes.

Coupla days later....

I ended up making two blades, the 5mm I mentioned above, and a 3mm, installed in the plough shown here.

I took them out yesterday to heat-treat in Nick's Magical Oven of Wonder, and ground and sharpened them today for their first outing.

They work perfectly, so I'd call that experiment a rousing success.

I still need to sort out some sort of depth-stop, and a new nipper for the skate would be a useful addition too.

Something I hadn't really noticed before, not having actually used the plane to any extent, is that it's set up for left-handed use — the off-hand knob and the fence is on the right-hand side. I believe, back in olden times, cabinetmakers would have two of these planes, so that you could use one in either direction if, for example, you had some troublesome grain or something to deal with, or for when the geometry of the piece didn't suit a left-hand fence. I can still use it right-handed, it's just a little awkward.