I've figured out a way of getting properly registered colour separations (and, eventually, prints).

I've built a frame on a piece of MDF which closely surrounds the block on three sides. Outside that frame are registration tabs to set the paper into, so the paper and block are always in exactly the same place, relative to each other. All the blocks are precisely the same size, so it works for all of them.

The frame around the block is the same thickness as the MDF I've cut the block from, which means that there's a support for the baren to run on to — that helps to keep it out of the voids, and it also means that it's less likely to shift the block by pressing against an outside edge. There's a floating piece, not attached, that I put across the right-hand edge after the block is in place for the same purpose.

The colour block guide prints are created by an offset printing process. The key block (the one in the frame in this photo) is printed on to a sheet of mylar, registered in the paper registration tabs. Then it and the key block are removed, one of the colour blocks put into the frame, and the mylar replaced against the registration tabs, and rubbed down against the fresh block with a rubber brayer (roller). That transfers a reversed image of the key block in perfect registration, and I can use that image to guide me in cutting the colour block.

I've put up a cheap portable washing line in my workshop that I can use for drying prints. These ones are on A3 sheets, and I figure I could get about 30 up there before they started to interfere with my printing area. I'm unlikely to be doing any large runs, so that should be plenty.

Friday, September 29, 2017

Registration and Separations

Tuesday, September 26, 2017

New-Model Baren (Mk.II & III)

|

| At top, Baren Mk.I, the one I've been using up until now On the right, Baren Mk.II (8mm cabochons), and to the left, Mk.III (12mm). |

The disks are 120mm in diameter, cut from 3mm hardboard. Hardboard is more hard-wearing and less vulnerable to water than MDF; it's not likely that these will ever get significantly wet, but better safe than sorry. The cabochons are glued to the disks with 24-hour cure epoxy resin (so they won't be ready for use until tomorrow at the earliest).

Both of the new ones are wider and flatter than the first one I made, which should make it less likely that they'll push paper down into the voids of a block where excess ink can often be found. The 8mm beads make for the flattest surface of course, with the largest number of contact points; I suspect that will also make it the hardest, physically, to use, as it will require more strength to keep all those points in firm contact with the paper surface. The proof of the pudding will be, as they say, in the eating. I won't know for sure until I actually start using them.

The 8mm beads have been laid out in a regular grid, while the 12mm beads were laid out in decreasing concentric circles. What difference (if any) that will make, I don't know; I'd like to try the less regular layout with the smaller cabochons, but I'll have to order some more in that case as I've used up almost my entire supply on this one.

Friday, September 22, 2017

Linocut

|

| That gouge is a very shitty gouge. Really, really shitty. |

Like lino, it's not great at reproducing very fine detail, but then if I want that I'll use wood.

It's not without its faults though. It repels water, so I can't draw directly on to the block with brush and indian ink as is my preference. Nor does it accept solvent transfer from a photocopy or laser print. A pencil line is quite indistinct against the green or blue background. I can draw on it with a Sharpie, so at least there's that.

I have some 75mm (3") Speedball soft rubber brayers, and I like them, but they're rather too narrow for me. I'd like some at least twice that width; the smaller ones have a tendency to fall into voids and leave ink where it's not wanted, so open areas have to be cut a bit deeper than would otherwise be necessary to keep them from printing.

My glass-bead baren, though otherwise excellent, is also a bit small, and the individual cabochons a little large. I'm waiting on some smaller glass cabochons, and when they arrive I'll make a wider, flatter one.

Saturday, September 9, 2017

Friday, September 8, 2017

The Proof Is Out There

|

| The block |

|

| The first proof |

I was originally planning to cut away the blank background areas completely, to eliminate the chance of any accidental ink contamination, but then I realised that would make registration placement quite difficult. So instead, I carved them away quite deeply so that the brayer (ink roller) doesn't touch them. I'll probably also give them a couple of coats of gloss varnish, so that if I do get ink in those areas I can just wipe it away.

The first proof (right) was pretty successful. There are a couple of areas that could do with a bit of extra cutting, but overall I'm fairly happy with it.

I can see that I'm going to have to be quite careful with the baren at the ends of the block — you can see a faint patch at bottom right where I skipped over it a bit.

Next up, I shall build a registration frame and start working out the colour blocks.

Thursday, September 7, 2017

Block Cutting

I'm cutting my first block in quite some considerable time, and my hands and neck are cramping up something awful. This is the key block; I'm thinking the finished print will be in three or maybe four colours, so of course blocks will have to be carved for each of them as well.

I'm using MDF, which isn't the best material in the world for block making, but it has some advantages. It's cheap and easily available, and it has no grain, which makes carving it a lot more like linocut than woodcut — your knife or gouge isn't going to be deflected by an unexpectedly hard and twisty bit of grain. However, it's rather fibrous, and if your tools aren't scalpel-sharp it tends to tear. It's pretty hard on tool edges too, so you need to be sharpening fairly often.

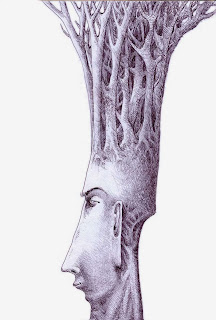

The image is one that I drew a few years ago, in ball-point pen.

I did a solvent transfer of a laser print of it on to the MDF, and then over-drew it with brush and Indian ink — I find that a brush drawing works quite well as a cutting guide, as I can't get too finicky about detail that I'd never be able to cut. For an image like this, the brush line changes the character of the image somewhat, but I like that; there seems little point to me in trying to force one medium into replicating another.

The small print you see in the main image is just a quickie I took early on in the cutting to see how the cutting will reproduce. That ink should be red, but it's been sitting in its tube so long that it's separated out, and despite all the kneading and massaging of the tube I could do, it stubbornly persists in squirting out mainly its chrome yellow base. I did the test print in a colour other than black because I wanted to still be able to see my ink lines afterwards.

I'm using MDF, which isn't the best material in the world for block making, but it has some advantages. It's cheap and easily available, and it has no grain, which makes carving it a lot more like linocut than woodcut — your knife or gouge isn't going to be deflected by an unexpectedly hard and twisty bit of grain. However, it's rather fibrous, and if your tools aren't scalpel-sharp it tends to tear. It's pretty hard on tool edges too, so you need to be sharpening fairly often.

The image is one that I drew a few years ago, in ball-point pen.

I did a solvent transfer of a laser print of it on to the MDF, and then over-drew it with brush and Indian ink — I find that a brush drawing works quite well as a cutting guide, as I can't get too finicky about detail that I'd never be able to cut. For an image like this, the brush line changes the character of the image somewhat, but I like that; there seems little point to me in trying to force one medium into replicating another.

The small print you see in the main image is just a quickie I took early on in the cutting to see how the cutting will reproduce. That ink should be red, but it's been sitting in its tube so long that it's separated out, and despite all the kneading and massaging of the tube I could do, it stubbornly persists in squirting out mainly its chrome yellow base. I did the test print in a colour other than black because I wanted to still be able to see my ink lines afterwards.

Friday, September 1, 2017

Baren Test

I gave my glass-bead baren its first test outing today. I used water-soluble Flint relief printing ink, applied to a roughly 120mm square MDF block with a rubber brayer.

This one is one very thin, smooth note paper, and it was pretty easy to get a fairly clean, sharp impression. I need to pay close attention to keeping the paper in place though; the first one I did moved about a bit under the rotational thrust of the baren, but it's not really difficult to keep it still if I pay attention.

This one is on fairly heavy printmaking paper — I don't know the manufacturer — about 280-300 gsm, I'd guess.

The impression is not as clean as on the thinner, smoother paper, which is not unexpected, but it's not too bad. It's worst at the bottom of the print, which I think is because I was a bit uneven in my rubbing pressure.

What I've learned from this very brief test is that the glass beads work very well as a baren surface, moving smoothly and easily over the paper surface, and it's easy to get a good amount of pressure without having to grunt and strain. However, I think it would work better with more, smaller beads, more closely spaced, so I'll see what I can find and make a second one.

This one is one very thin, smooth note paper, and it was pretty easy to get a fairly clean, sharp impression. I need to pay close attention to keeping the paper in place though; the first one I did moved about a bit under the rotational thrust of the baren, but it's not really difficult to keep it still if I pay attention.

This one is on fairly heavy printmaking paper — I don't know the manufacturer — about 280-300 gsm, I'd guess.

The impression is not as clean as on the thinner, smoother paper, which is not unexpected, but it's not too bad. It's worst at the bottom of the print, which I think is because I was a bit uneven in my rubbing pressure.

What I've learned from this very brief test is that the glass beads work very well as a baren surface, moving smoothly and easily over the paper surface, and it's easy to get a good amount of pressure without having to grunt and strain. However, I think it would work better with more, smaller beads, more closely spaced, so I'll see what I can find and make a second one.

Subscribe to:

Posts (Atom)