Wednesday, December 27, 2017

From Useless Rasp to Useful Marking Knife

I have a set of really terrible wood rasps that I bought very cheaply years and years ago. They're bad rasps.

I finally got around to making the flat one a useful tool by cutting it up and grinding off its teeth and turning it into a marking knife.

The only issue with it is that the divots left behind after grinding it flat means that it can't be ground sharp with a single bevel; it has to be beveled on both sides, or else the divots will create notches in the edge. I can live with that, but it would be better made from a very fine mill file or an old chisel.

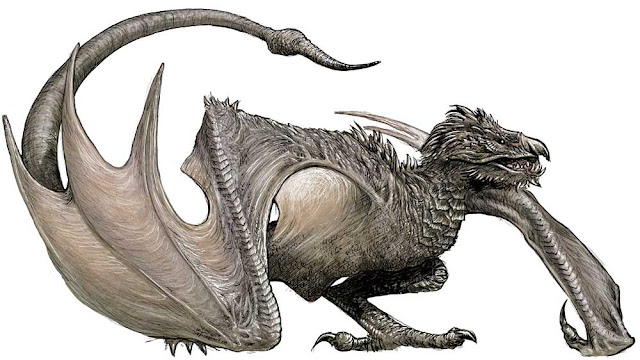

Wyvern

I drew this wyvern for my AD&D campaign journal. It's based on a render of a critter I found on the internet, but unfortunately I don't know who did that original design. I've made my one a bit knobblier though.

It's all been done digitally in Krita, a free open-source paint program that I highly recommend.

It's all been done digitally in Krita, a free open-source paint program that I highly recommend.

Sunday, December 10, 2017

Paper Towel Holder

|

| In all its naked glory |

|

| Fulfilling its purpose |

The base is about 160mm in diameter and 50mm thick, and that much mass of oak is sufficient to create a bit more vibration in the lathe than I've been used to — especially before I realised I hadn't screwed the wood hard up to the face-plate on one side, so everything was turning slightly skewed. It got a bit better after I attended to that, but I don't think my little lathe would be very happy with anything much bigger than this.

Friday, December 8, 2017

Rough-Sawn Macrocarpa Stool

This is a stool entirely for the Outside, that I whipped up in a few hours from a macrocarpa board I found hiding away down the back of the section.

It's very simple, and as far as is possible, without subjecting its users to the dangers of splinters, I've kept the original rough-sawn finish — I've just sanded it down a bit to smooth it off.

I've applied no finish to this one. I'll just leave it out in the weather, and over a couple of years it will develop its own silvery weather-beaten patina.

It's very simple, and as far as is possible, without subjecting its users to the dangers of splinters, I've kept the original rough-sawn finish — I've just sanded it down a bit to smooth it off.

I've applied no finish to this one. I'll just leave it out in the weather, and over a couple of years it will develop its own silvery weather-beaten patina.

Monday, December 4, 2017

Three-Legged Stool

I made the legs for this stool playing around on my new lathe, and they're as long as it can manage in its present configuration, which is about 420mm.

I'm not usually all that keen on staining wood; I'd rather just oil it and let the natural grain and colour come out. But this is made out of low-grade H4 treated pine, which has a rather unpleasant murky grey-green cast to it, so I coloured it to disguise that.

The stool is solid and comfortable to sit on, but aesthetically I think the legs could have done with another few degrees of rake.

I'm not usually all that keen on staining wood; I'd rather just oil it and let the natural grain and colour come out. But this is made out of low-grade H4 treated pine, which has a rather unpleasant murky grey-green cast to it, so I coloured it to disguise that.

The stool is solid and comfortable to sit on, but aesthetically I think the legs could have done with another few degrees of rake.

Sunday, December 3, 2017

Chisel Handle

A friend has loaned me a great armful of turning tools (thanks!), some in dire need of some TLC and others needing little more than a scrub up with steel wool and some sharpening.

I've got some of the rustier ones in a vinegar bath right now, and I used some of the cleaner tools to whip up this chisel handle out of white oak. The ferrule is a copper plumber's gland, the striking hoop is a bit of copper pipe.

I don't actually have a need for a chisel handle right at this minute, but I wanted to practice turning to precise sizes (for the ferrule and striking hoop). I'm doing it at the moment with the aid of calipers, but there's a tool that clamps on to a cut-off tool or scraper that makes the process almost idiot-proof, and I'd like a bit of idiot-proofing.

I've got some of the rustier ones in a vinegar bath right now, and I used some of the cleaner tools to whip up this chisel handle out of white oak. The ferrule is a copper plumber's gland, the striking hoop is a bit of copper pipe.

I don't actually have a need for a chisel handle right at this minute, but I wanted to practice turning to precise sizes (for the ferrule and striking hoop). I'm doing it at the moment with the aid of calipers, but there's a tool that clamps on to a cut-off tool or scraper that makes the process almost idiot-proof, and I'd like a bit of idiot-proofing.

Friday, December 1, 2017

New Lathe

I spent all my meagre savings on a small wood-turning lathe for myself. It's pretty good for the price; a decently solid cast-iron construction that gives minimal vibration, and a 5-speed pulley system. The maximum distance between centres is about 420mm, so maybe just long enough to turn a chair leg on — there's an extension available for the bed though, which I may invest in at a later date if I find I need it. The only thing about it that I'm not that impressed with is the tool rest, which is very short, only 150mm (6") long. That will need to be addressed at some stage.

I enjoyed turning when I did it at 'tech, but I've done very little of it, and none at all for years, so what skills I had are now very, very rusty. It's going to take a bit of practice to get my hand back in.

My first very modest practice piece is this awl handle, made from a scrap of oak. The blade is an old 3mm drill bit shank.

Oak is a bit mixed as a turning wood. It's hard enough to cut crisply, but it has a fairly open grain, so the surface never looks as smooth and clean from the knife as fruit woods like apple or cherry. However, that's what I've got, so that's what I'm practicing on.

I enjoyed turning when I did it at 'tech, but I've done very little of it, and none at all for years, so what skills I had are now very, very rusty. It's going to take a bit of practice to get my hand back in.

My first very modest practice piece is this awl handle, made from a scrap of oak. The blade is an old 3mm drill bit shank.

Oak is a bit mixed as a turning wood. It's hard enough to cut crisply, but it has a fairly open grain, so the surface never looks as smooth and clean from the knife as fruit woods like apple or cherry. However, that's what I've got, so that's what I'm practicing on.

Subscribe to:

Posts (Atom)